PRODUCTS产品中心

Home >Horizontal dual station hydraulic die head machine

Service Hotline

13864796766

The main structural features of the 10T hydraulic dual station die head wax injection machine are:

1. The horizontal dual station four column mold closing mechanism has mold hanging screw holes on the side closing template, upper closing template, and middle plate, and a mold ice water interface is reserved on the equipment.

2. The rear injection nozzle can be freely adjusted in three dimensions within a vertical plane, greatly facilitating the alternating use of large and small molds.

3. The left and right workstations have a shared wax box, two independent wax outlets, and separate wax extrusion cylinders to ensure independent wax supply and coordinated stable operation.

4. To ensure that the wax temperature can be maintained below 58 ℃, a two-stage cooling mechanism of mechanical stirring rapid cooling and composite tube cooler is adopted, so that the wax is injected from the wax nozzle at a constant temperature, and the wax mold is stable and of good quality.

5. The electrical control has dual functions of manual and automatic, and is controlled by a PLC program controller.

6. The wax injection pressure and mold closing pressure can be adjusted through a pressure regulating system, and the side mold closing cylinder and upper mold closing cylinder can be selected for action. The cooling time and holding time can be freely set according to process requirements.

7. The wax ducts of the entire machine are insulated by forced convection of thermal oil, making the temperature more uniform. At the same time, the insulation heat is taken from the wax liquid to save energy.

8. All mechanical actions of the entire machine are driven by the hydraulic system, ensuring the stability of the system.

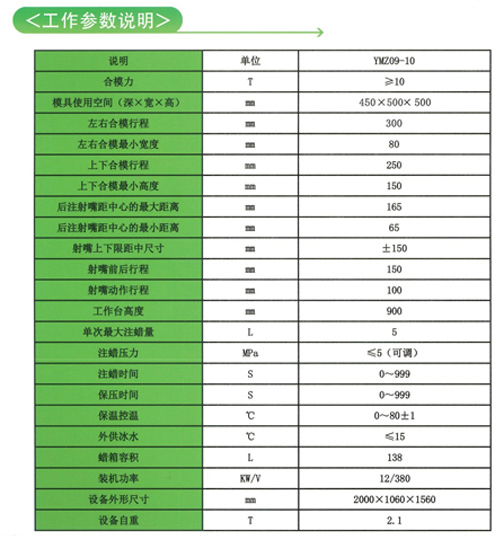

Configuration Instructions

1. Electrical components: Chint or Schneider, PLC programmers use Taiwan's Delta series, and proximity switch series components use Japan's Omron.

2. Hydraulic system: The hydraulic valve is from Taiwan Oil Research Institute; Hydraulic motor for Taiwan Qunce; The hydraulic pump is from Taiwan Oilfield; The circulating motor pump is from Taiwan Weiliang; The cylinder seal is made of Japanese NOK; The oil cylinder is from Jinan Yuci Branch.

3. The host is made of discounted δ 4 hot plates, and the inner layer of the wax box is welded with 304 stainless steel plates. The wax cooling system is welded with three layers of tubes, and all the wax conveying tubes are pickled and phosphated.