PRODUCTS产品中心

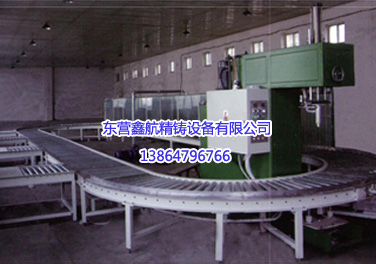

Home >Wax pattern production cycle line

Service Hotline

13864796766

1、 Product Features

1. Each set of molds can run automatically on the circular production line track, eliminating the labor intensity of mold handling and saving manpower.

2. Each set of molds is automatically controlled for wax injection pressure, wax injection time, and holding time. Excluding human factors, the quality of wax molds is stable.

3. When each set of molds passes through the tunnel freezer, it can be divided into several cooling times, and automatic control of mold cooling time can be achieved through stepless speed regulation.

4. This mold can be operated manually or automatically from the mold lifting workbench position. The workbench is equipped with a mold lifting device, which can achieve mold flipping and horizontal rotation. Reduce the labor intensity of mold making operations.

5. Continuous production is possible, and one device is equivalent to multiple devices.

6. The wax bucket of this machine comes with a built-in mixer to prevent uneven temperature caused by the transportation of wax paste through pipelines.

2、 Technical parameters

1. Machine model (DHX09-10 * 5)

(1) Mold space: 600 * 600 * 600mm

(2) Maximum wax injection volume: ≤ 18L

(3) Wax injection pressure: 0.2-1.0MPa

(4) Gas source pressure: ≥ 0.5MPa

(5) Power: 20.8KW

(6) Floor area: 15 * 6m

2. Machine model (DHX09-16 * 8)

(1) Mold space: 700 * 700 * 700mm

(2) Maximum wax injection volume: ≤ 24L

(3) Wax injection pressure: 0.2-1.0MPa

(4) Gas source pressure: ≥ 0.5MPa

(5) Power: 24KW

(6) Floor area: 21 * 6m